SERVICES

Dose and energy calibrations are of critical importance as they affect the quality control processes of your products but they also have an impact on the performance of your accelerator if it is not controlled on a regular basis

Regular dose calibration should be carried out on all accelerators. We offer this service on your site. How do you know you are not overdosing your products ? The elongation test on the final products only shows you that the product has reached the required specifications, but it could be done with a lesser dose as well. The on site dosimetry will help you to optimize and validate your recipes.

On electron accelerators, the energy has to be calibrated on a regular basis. On most sites, the energy is under-evaluated, meaning that the real energy of your accelerator is higher than the displayed energy on the control system. This has some consequences on the accelerator components themselves but it also leads to unnecessary electrical consumption.

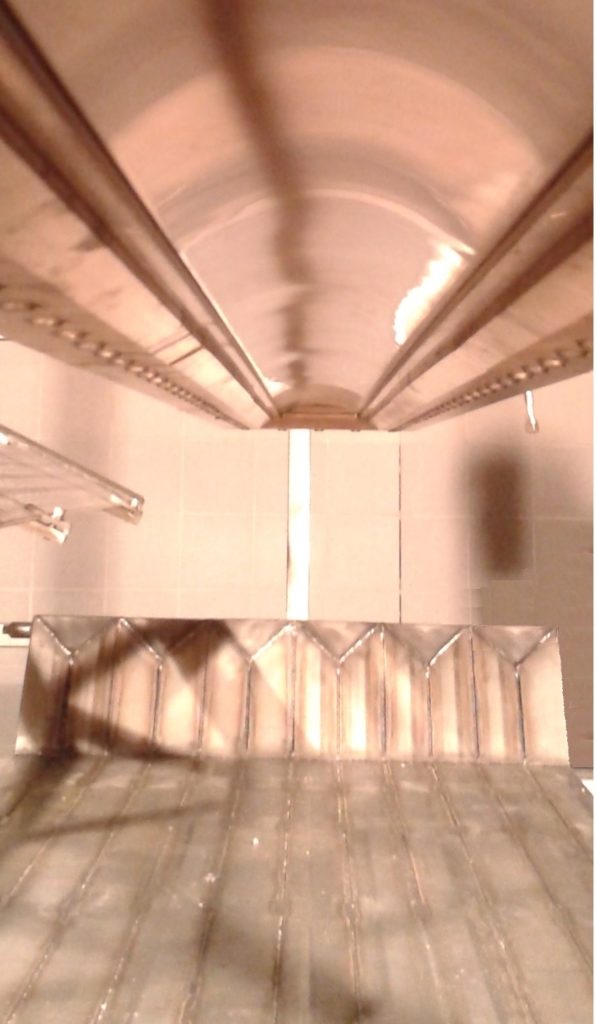

In order to recalibrate the energy, some depth dose packs are shot and then, analysed. With this analysis, we can calibrate the interpolation table and put your accelerator back on track.